Product Description:

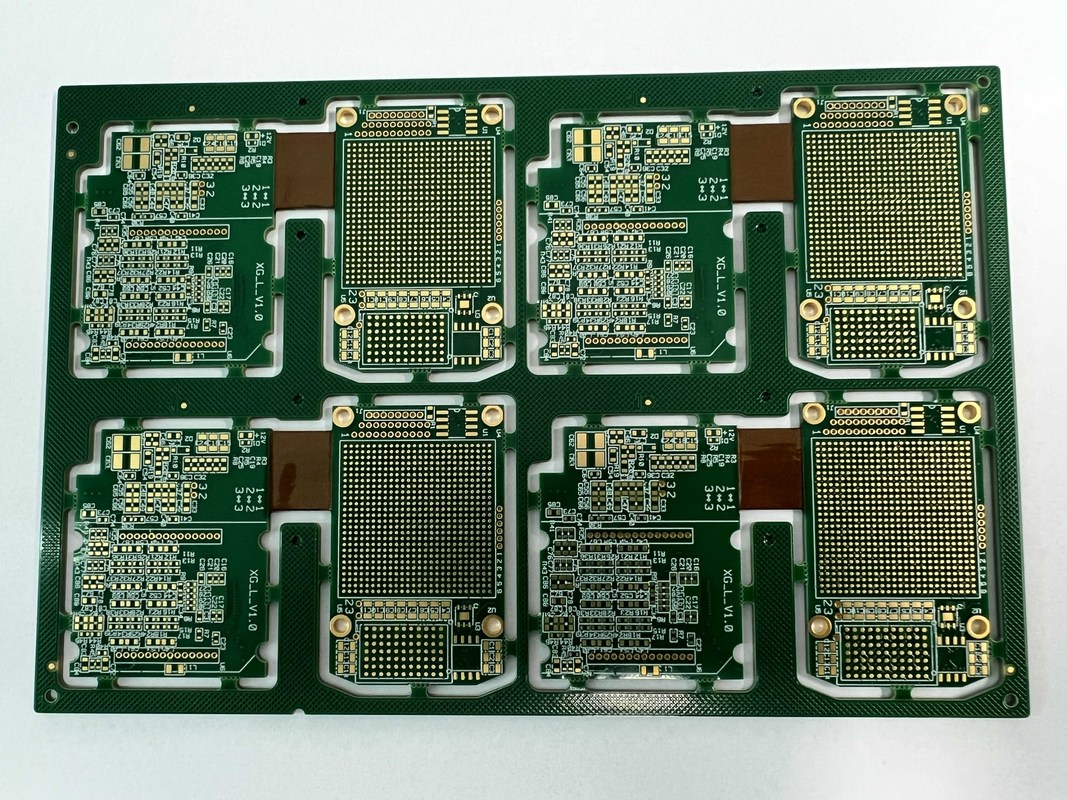

A Bendable Rigid Printed Wiring Board, commonly known as Rigid Flex PCB, is a unique type of circuit board that combines elements of both rigid and flexible PCBs, offering enhanced flexibility and reliability for diverse electronic applications. This revolutionary product is designed to provide the best of both worlds, enabling seamless integration of rigid and flexible areas within the same board.

Our Rigid Flex PCB comes with a variety of Stiffener Options to meet specific design requirements. These options include Polyimide, FR4, and Stainless Steel stiffeners, each offering distinct characteristics to enhance the overall durability and flexibility of the board. Whether you need a lightweight and flexible solution or a more rigid and robust structure, our Rigid Flex PCB can be customized to suit your unique needs.

The Outer packaging of our Rigid Flex PCB is carefully handled to ensure maximum protection during shipping and handling. All boards are securely packaged in Carton Boxes to prevent any damage or deformation, guaranteeing that your product arrives in pristine condition ready for installation.

With a remarkable Max Layer capability of 52L, our Rigid Flex PCB offers extensive design flexibility for complex electronic systems. Whether you require multiple layers for advanced circuitry or intricate signal routing, our high layer count ensures that your board can accommodate a wide range of functionalities without compromising performance.

When it comes to precision, our Rigid Flex PCB excels with a Min Line Space of 8mil, allowing for intricate and detailed circuit designs. This feature is particularly beneficial for applications that demand high-density components and precise signal integrity, ensuring optimal performance and reliability in even the most demanding environments.

Our Rigid Flex PCB is compatible with a wide range of Components including Surface Mount Devices (SMD), Ball Grid Arrays (BGA), Dual In-line Packages (DIP), and many more. This versatility enables you to integrate various types of components seamlessly into the board, making it suitable for diverse electronic assemblies and applications.

In summary, our Rigid Flex PCB is a cutting-edge solution that combines the benefits of a Bendable Rigid Printed Wiring Board with the flexibility of a Flex Rigid PCB and the durability of a Flexible Stiff Circuit Board. With customizable Stiffener Options, robust Outer packaging, high layer count, precise line spacing, and compatibility with various components, our Rigid Flex PCB is the ideal choice for demanding electronic projects that require reliability, flexibility, and performance.

Features:

-

Product Name: Rigid Flex PCB

-

Surface Finishing: Lead Free HASL

-

Min. Line Width/Spacing: 0.075mm/0.075mm

-

Processing: Assembly

-

Outer: Carton Box

-

Components: SMD, BGA, DIP, Etc.

-

Keywords: Flexible Rigid Circuit Board, Bendable Printed Circuit Board, Rigid Flex Printed Wiring Board

Technical Parameters:

|

Surface Finishing

|

Lead Free HASL

|

|

Min. Line Width/Spacing

|

0.075mm/0.075mm

|

|

Size

|

9*9cm

|

|

Min Line Space

|

8mil

|

|

Processing

|

Assembly

|

|

Surface Treatment

|

HASL Lead Free, Immersion Gold

|

|

Components

|

SMD, BGA, DIP, Etc.

|

|

Thickness

|

0.6mm

|

|

Stiffener Options

|

Polyimide, FR4, Stainless Steel

|

|

Max Layer

|

52L

|

Applications:

The Rigid Flex PCB product is a versatile solution suitable for a wide range of product application occasions and scenarios due to its unique attributes. With a minimum line space of 8mil and a layer count of 16 layers, this Flexible Stiff Circuit Board offers a high level of design flexibility and complexity. The ability to incorporate multiple layers enables the product to be used in advanced electronic devices and applications that require intricate circuitry arrangements.

The Stiffener Options available for the Rigid Flex PCB include Polyimide, FR4, and Stainless Steel, providing varying levels of rigidity and durability based on the specific requirements of the application. This flexibility in stiffener options makes the product ideal for use in diverse industries such as aerospace, medical devices, and automotive electronics where reliability and performance are critical.

In terms of Surface Treatment, the Rigid Flex PCB offers options such as HASL Lead Free and Immersion Gold, ensuring superior solderability and corrosion resistance for enhanced product longevity. These surface treatments make the product suitable for applications in harsh environments or where exposure to moisture and other elements is a concern.

One of the key features of the Rigid Flex PCB is the requirement of Gerber/PCB File for its fabrication, allowing for precise customization and manufacturing based on the specific design needs of the customer. This feature is particularly beneficial for industries such as telecommunications, consumer electronics, and industrial automation that demand high-quality and reliable printed circuit boards.

Overall, the Rigid Flex PCB, also known as Flexible-Bendable PCB or Bendable Rigid Printed Wiring Board, is a versatile and reliable solution that can be applied in a wide range of product development scenarios where flexibility, durability, and performance are essential.

Customization:

Product Customization Services for the Flex Rigid PCB:

Outer: Carton Box

Solder Mask Colour: Green

Surface Treatment: HASL Lead Free, Immersion Gold

Finished Copper: 1OZ

Max Layer: 52L

Support and Services:

The Rigid Flex PCB product offers comprehensive product technical support and services to ensure optimal performance and reliability. Our team of experts is dedicated to assisting you with any technical inquiries, troubleshooting issues, and providing guidance on product usage and integration.

Our technical support services cover a wide range of areas such as design consultation, material selection, prototype development, testing, and compliance assessment. We are committed to delivering high-quality support to meet your specific requirements and help you achieve your project goals.

Additionally, we provide services to address any maintenance or repair needs, ensuring the ongoing functionality and durability of your Rigid Flex PCB product. Our experienced technicians are available to offer assistance and solutions to keep your systems operating at peak performance levels.

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!